Overview

Fire door assemblies have been utilised for decades to protect openings in buildings where fire-rated construction is deemed essential. These doors are evaluated for their fire performance in accordance with the requirements of AS1905 Part 1: Components for the protection of openings in fire-resistant walls – Fire-resistant doorsets, as per the test methodology outlined in AS1530 Part 4: Fire resistance tests of elements of building construction.

In more recent times, ‘smoke control door assemblies’ have been utilised to limit the spread of smoke through door openings. These smoke control door assemblies either meet the deemed-to-satisfy requirements of the NCC Specification C3.4, or are tested in accordance with the design requirements of AS6905: Smoke Doors, as per the test methodology outlined in AS1530 Part 7: Methods for fire tests on building materials, components and structures. Part 7 – Smoke control assemblies – ambient and medium temperature leakage test procedure. The latter representing a Performance Based Alternative Solution (permissible under the NCC), allowing industry to specify smoke doors with a quantifiable level of performance.

Performance testing

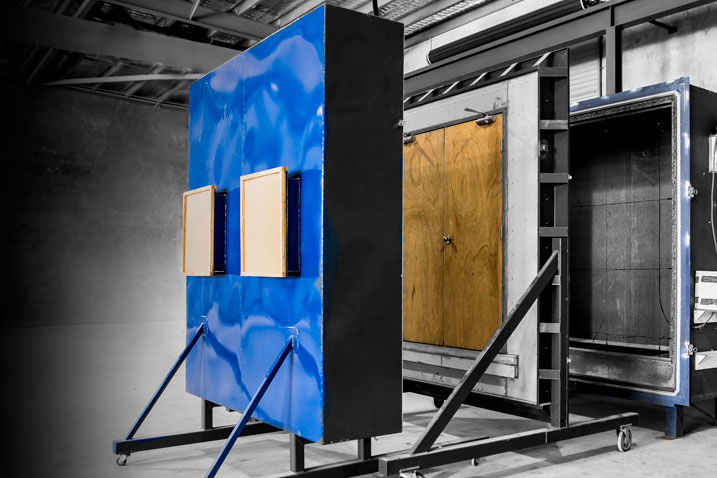

Our facility

The facility consists of a lined, steel test chamber, with heat-resistant, airtight seals installed around the aperture perimeter. The test specimen holder is clamped to the chamber upon commencement of the test process.

The test chamber has an internal opening of 2480mm (w) x 2460mm (h), whilst the specimen holder is able to accommodate specimens up to and including a maximum 2280mm (w) x 2360mm (h).

More from Resolute

Resolute Labs is capable of undertaking a wide range of other testing based on our clients’ requirements. Please contact us to discuss your needs and find out how we can work with you to complete your project.

Contact us today to find out more.